Printed Bubble Free Vinyl

5 Year Air Release Vinyl has tiny channels in the adhesive which allows for easier fitting. Ideal for use indoors or outdoors, issues of air bubbles and creasing are very much reduced. The air release channels are minute criss-cross lines imprinted on the adhesive side of the vinyl film. When applying the vinyl, the system allows air to travel, which prevents air pockets or bubbles. Air release vinyl is 70 micron plus matching overlaminate of 70, making a total of 140 micron.

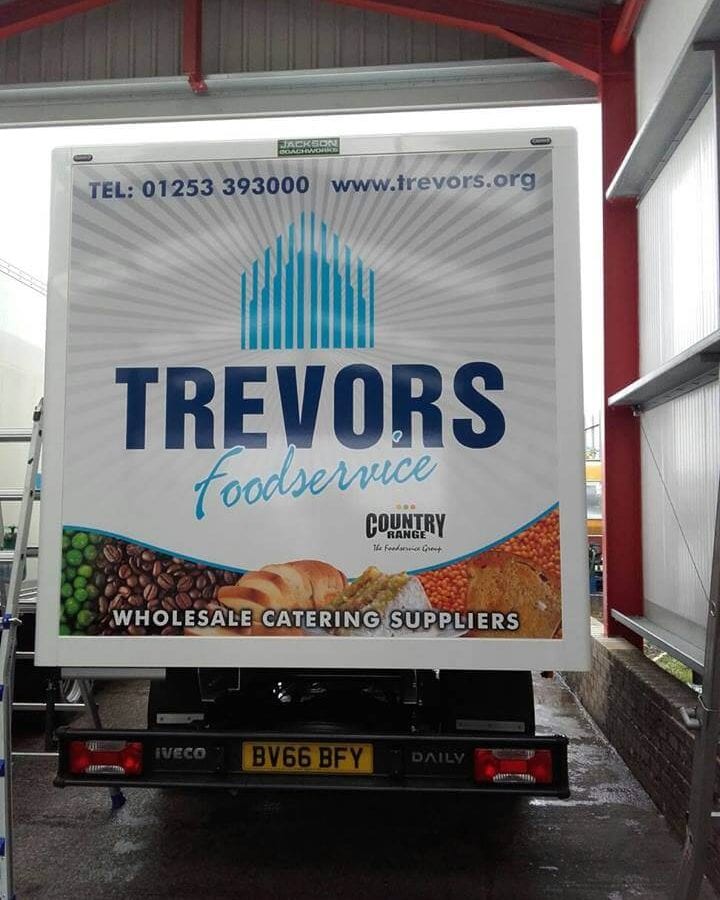

Air release vinyl graphics

Air release printable vinyl can be cut into complex shapes. We offer Gloss or Matt lamination as standard, and you can select the finishing of your vinyl on step 2 of the ordering process. We produce any Air release vinyl stickers to your custom requirements. Our anti-bubble printed vinyl is available in widths up to 1.32m. Larger graphics will require a join with overlap. You can specify the amount of overlap you require when ordering. Place a note on your order when going through the ordering process to let us know your overlap requirements.

Easy Apply Vinyl Prints

Easy apply printed vinyl is the perfect material when flooding large areas. Perfect for covering large wagon sides or any large flat surface or panel. The anti-bubble system makes for the easy application on large areas, reducing the time taken in popping or re-lifting in bubbled areas. As the name suggests, easy-apply vinyl printing is much quicker to install than standard vinyl films making your work much quicker, so the material is more cost-effective in the long term.

Anti-Crease vinyl Printing

Air release vinyl also has anti-crease properties. Because the airflow channels remove trapped air, this means that our bubble resistant vinyl printing is less likely to crease. On a standard film without channelling the air becomes trapped, creating a high point which is easily caught with your squeegee creating a crease. If a crease happens, you would need to lift the vinyl and start over. The problem with lifting vinyl is that it tends to stretch, which can cause problems when reapplying, becoming very awkward for a novice installer to overcome. Using printed anti-bubble vinyl makes applying large areas very easy and efficient.

Best air release vinyl for a novice installer

5yr Air Release Vinyl is the perfect product for novice installers. Avoiding bubbles and wrinkles during vinyl application is always recommended for a perfect installation. Air bubbles under vinyl will ruin your application’s finish, making Bubble free air release vinyl appealing to most installers. Easy to apply printed vinyl makes for fewer problems when applying as it favoured by sign installers with less experience in applying large graphics to panels. Will bubbles in vinyl go away? Yes with the airflow system moist bubbles will disperse.

How to put vinyl stickers on without bubbles?

For example, say you were applying vinyl to a large wagon. You would require vertical drops of printed graphic with overlap top and bottom to trim in afterwards. You would also require overlap on each tile, so each tile overlaps the next, creating a seamless graphic. Remember to start with the back tile first working forward. Start at the back, so water goes over the overlap. If you start at the front, water can work into the overlap from the vehicle’s forward motion.

The best practice of installing large air-release vinyl is using a hinge technique. Add pieces of masking tape top and bottom to hold the graphic, create a horizontal hinge along the middle, and then apply the top section using a squeegee and then the bottom section. For more details on application, please view our application blog post.

The Benefits of Air Release Vinyl

Faster Fitting

Fitting air release vinyl is faster for both inexperienced and experienced staff. The material goes on easier and smoother thanks to the air channels in the adhesive.

Less Waste

Even an experienced fitter can occasionally come across the issue of bubbles or creases in the vinyl once applied. Sometimes, creases can be so apparent that the only solution is to remove the vinyl and start again, causing waste and additional cost and time.

Better Finish

Air release vinyl provides a smoother finish more often than standard vinyl.

1 review for 5yr Air Release Vinyl

Ian Taylor (verified owner) –

Great value for money, excellent customer service. I wouldnt use anyone else.

Based on 113

Google Reviews