How to create artwork for banners with pole pockets?

Pole pockets are common on banners that are fitted to scaffolding or any other sort of framing.

Step 1

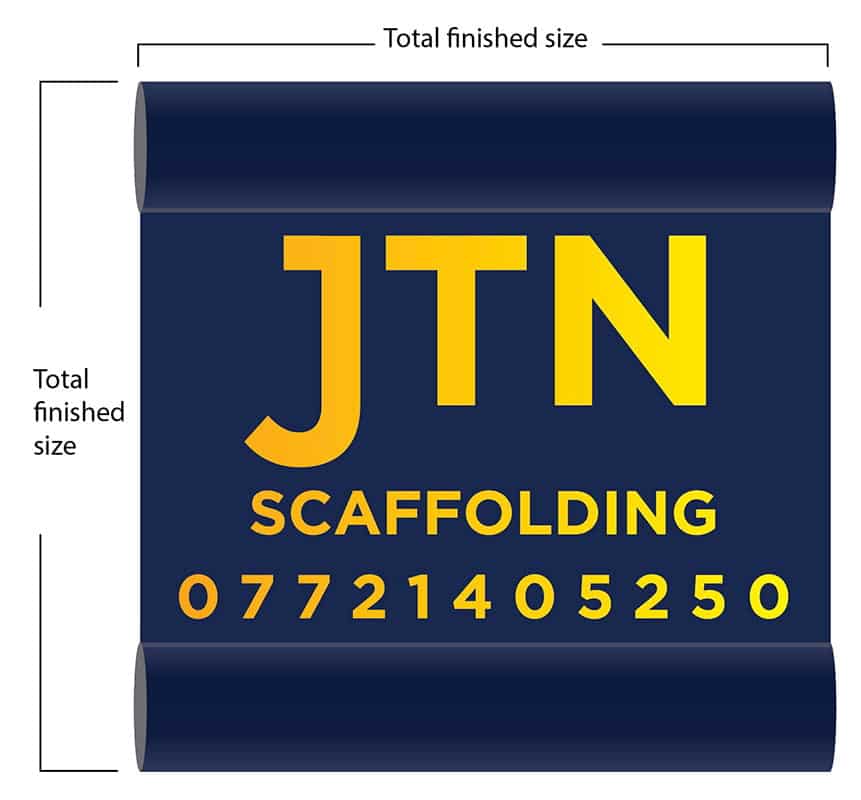

When creating artwork for a banner with pole pockets, set your artwork to your total finished size, including the pole pockets. The same applies when ordering. Please order your banner at the complete size, including the pole pockets.

Step 2

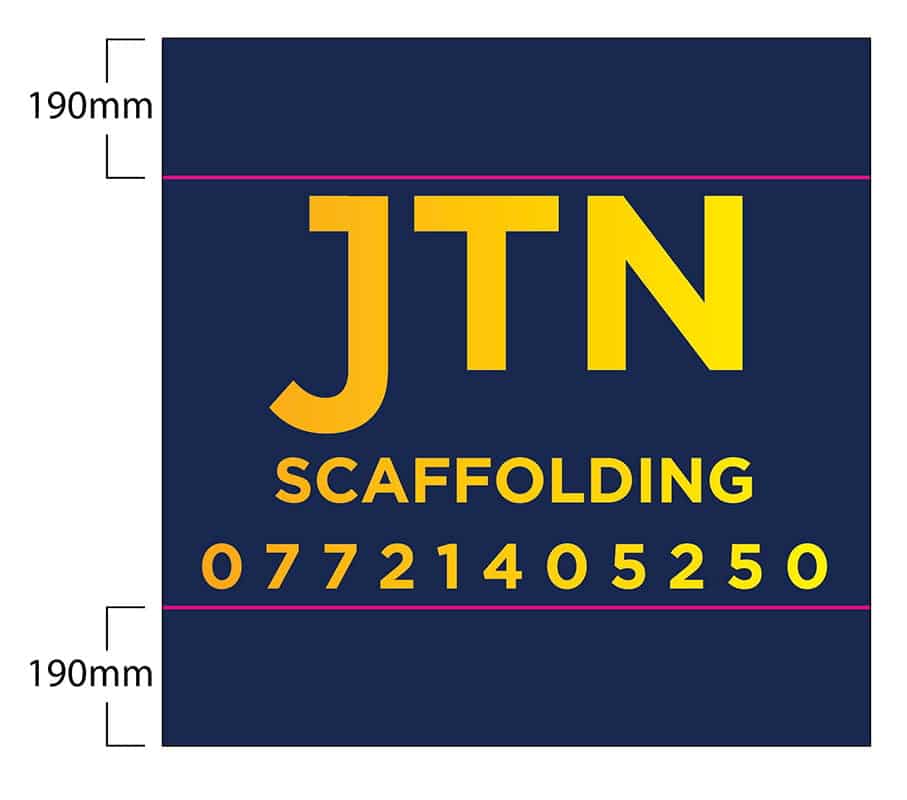

Remember to keep a safe area. Safe area refers to an area where we manufacture the pole pockets. We allow background colours, textures or images within this area, but text and logos must not fall into the safe area. For example, if you order a pole pocket of 150mm, then please set your safe area to 150mm + 40mm for the pole weld, so a total of 190mm.

What is a banner pole pocket?

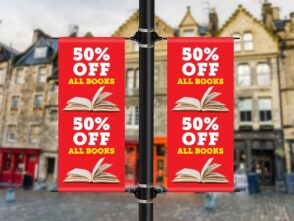

Banner pole pockets or banner sleeves is banner material folded over itself which creates an opening which we call a pocket. Pole pockets are usually placed along the top and bottom edges of a PVC banner. The folding over of the material enables a pole or cable to be inserted. Banner pole pockets are a perfect solution for banners that require fixing to a cable scaffolding or lamp posts.

What happens when I order a banner with pockets?

When we receive an order for a banner with pole pockets, we need to create extra material to make the rear of the pocket. We need this extra material so the pocket will fold over the reverse of the banner which creates the opening of the pocket. The material is folded over which we then weld to the reverse side of the banner. To create the weld, we use a process called high-frequency welding, which creates a super-strong joint.

What is high-frequency banner welding?

High-frequency welding joins the banner material together using an electromagnetic field and pressure. The resulting join creates a super durable join, and some cases even stronger than the original material. No outside heat source is used during the fusing of the material. Instead, the heat is created from the fusion process as the atoms fuse together.

What is reinforced banner pole pocket?

If additional strength is required, we also offer a reinforced pole pocket. A reinforced pole pocket features a welded seam, which is also over-stitched. The additional sewing of the pockets creates an extra bond between the two materials stitching them both together for extra durability.

Why do I need a banner pole pocket?

Banner pole pockets have a wide range of uses. Banners with pole pockets are favoured with scaffolders and tradespeople. Having a banner with pole pockets enables a banner to quickly attach to scaffolding or rigging by threading a pole through the pockets. Some internal banners and polyester fabric backdrops require pole pockets so that the backdrop can be attached to a stage or rigging system. You would usually find pole pockets on lamp post banners which have projecting poles top and bottom. Indoor hanging banner mostly features pole pockets and are usually fitting with a metal cable or thin rope. PVC Banners which hang inside at exhibitions or trade events would usually feature a pole pocket top for the insertion of a pole or cable but would also feature a pocket at the bottom. The purpose of the bottom pocket isn’t for fixing but to give the option to weight down the banner. Inserting a piece of wooden dowel or a weighted metal pole adds extra tension to an internal hanging banner which creates a taught and flat look. Adding a weight into the bottom pocket also avoids the banner from floating around with the movement of internal air from heating and ventilation units.

What is the Safe Area on pole pockets?

The term ‘safe area’ or ‘clear area’ refers to the areas of the face of the banner where the pole pocket is positioned. Clear areas are the areas where the pole pocket will be made, and this region shall be free of text, important logos and detailing. It is ok though in the safe area to have background colour and imagery. There is a reason as to why the safe area should be free of design elements, but on the other hand why it’s ok to use background colours. As you can imagine, this is where designers tend to get confused. To understand the reasons, we need to explain the manufacturing process.

How do we manufacture pole pockets?

To explain this, its best to offer an example. You order a PVC banner at 1m wide x2m height with 150mm pole pockets top and bottom. The finished height of your banner including the pole pockets is 2m. The area on which all the logos and information shall sit is within 1.6m. This measurement takes into account your safe area top and bottom as you need a safe area top and bottom of 200mm. You will need 150mm for the physical pockets and 50mm for the welded seam which equals 200mm.

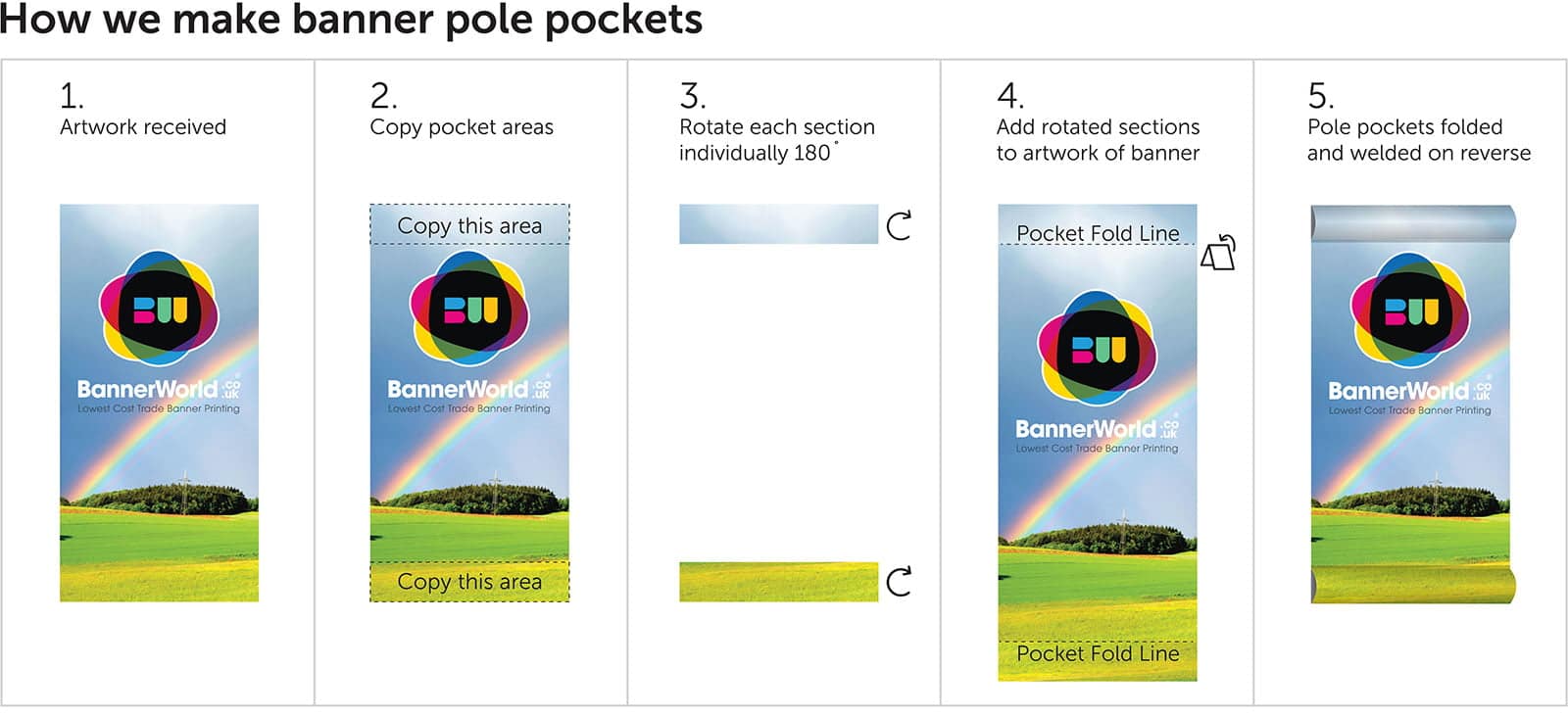

Our automated pole pocket software allows us to create banner pole pockets quickly and efficiently. Because we manufacture efficiently, we save you money, and we do not charge extra for pole pockets. Most supplies will add a premium for this service due to the additional setup and manufacturing costs. The below process and illustration explains in simple terms how we create banners with pockets.

We use unique software that completes the below steps when creating extra material for the reverse of the pockets on double sided banners.

- We receive the artwork with your clear area top and bottom.

- To create the pockets, we copy the top and bottom 200mm of the design.

- Next, we rotate each cropped area individually 180 degrees, creating the pocket sections for the opposite side of the banner.

- We paste the rotated and copied artwork onto the top and bottom edges of the banner. The copying process creates the additional material for the reverse side.

- We fold over the material and weld in place, giving a near-seamless join.

That’s the basic process of how we manufacture your banners pole pockets and the reason why we require a safe area. We use the same method when producing double-sided or single-sided banners. Because banners are large-format items, you will never full align text and logos up on the opposite side. To seamlessly join a banner to mm precision would be unachievable as we work with tolerances of around 5mm. Meaning that if we flip the side over which features text and logos, then the artwork won’t match. However, with background and solid colours, there is more tolerance due to the nature of the image etc.

What size pole pocket do I need on a banner?

Pole pocket sizes are dependant on the type of pole or cable diametre. The most popular size of pole pocket is a flat pocket size of 150mm which fits a standard scaffolding pole. Here is a list of sizes for different diameter poles and you can read our pole pocket guide for further reading:

Scaffold pole (50mm Diameter) – 150mm pocket (200mm including weld)

25mm diameter pole – 80mm pocket (120mm including weld)

30mm diameter pole – 90mm pocket (130mm including weld)

Flat pockets refer to the height of a pocket when laid flat. On a cafe barrier system, the top pole is around 30mm, and for this diametre, we product pockets at around 90-100mm.

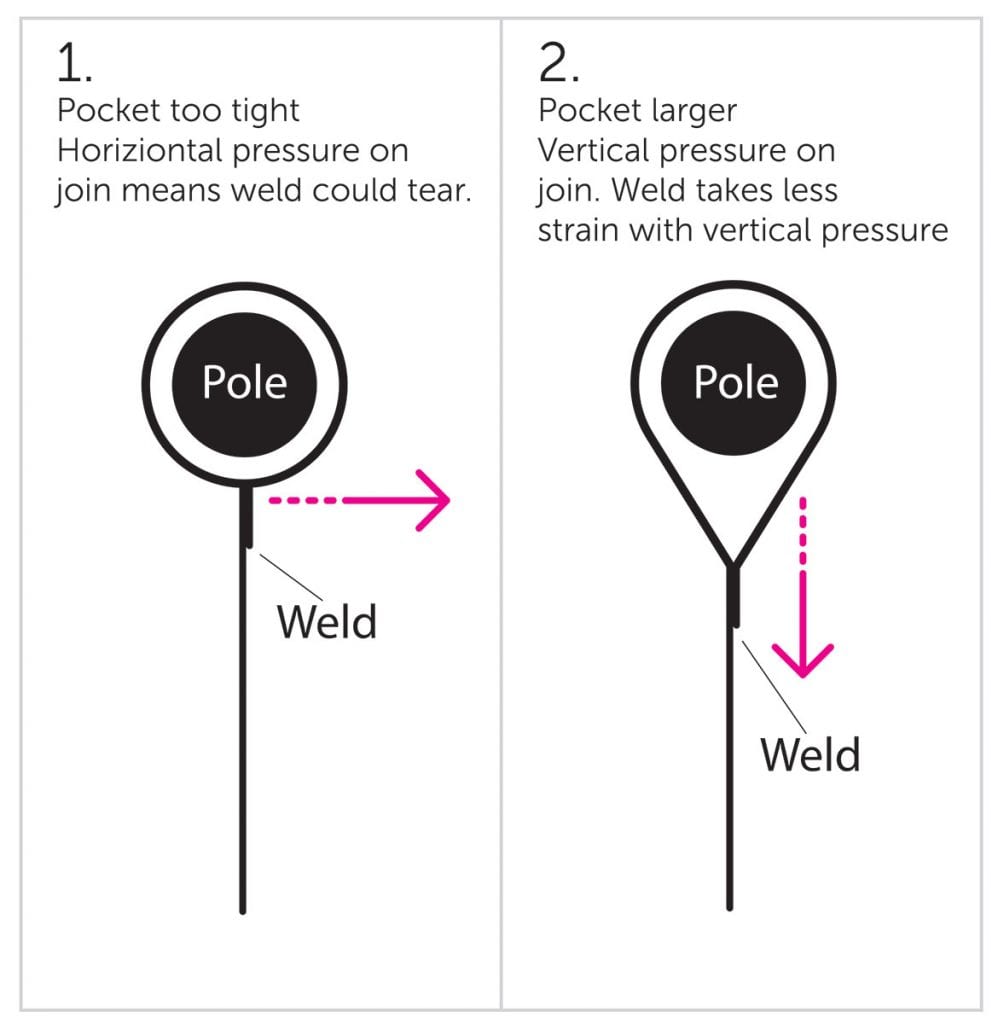

Why does the pole pocket need to be much wider than the pole? Making your pole pocket larger is always beneficial, and creating a slightly larger pole pocket puts less strain on the pocket weld. See image for an explanation on the extra stresses a small pocket has on printed banner and fabric material.

What are the benefits of a banner pole pocket?

The benefits for using pole pockets are that they can be fitted in scenarios where hem and eyelets won’t suffice. On banners, especially internal banners or flags for exhibitions pole pocket, offer a less cluttered appearance and are more aesthetically pleasing. Pole pockets, when used on scaffolding, have added durability because the whole vertical lengths are attached around the pole which spreads the fixing load. Pole pockets are more suitable for double-sided banners because they are more likely to be viewed from both sides. If you require a banner with pole pockets and supporting eyelets, we can also supply this finishing option. If you are unsure when ordering, please place a note on your order with your special request. If we have any questions on your order regarding your specific finishing information, we will make contact with you before production.

Leave a Reply

You must be logged in to post a comment.