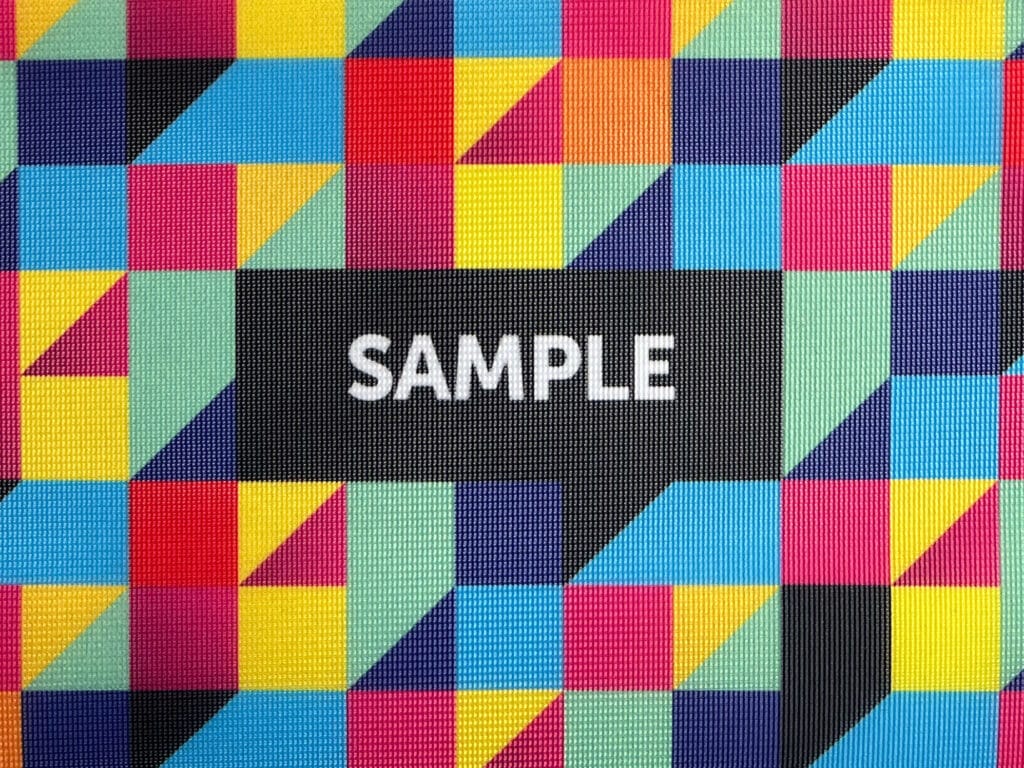

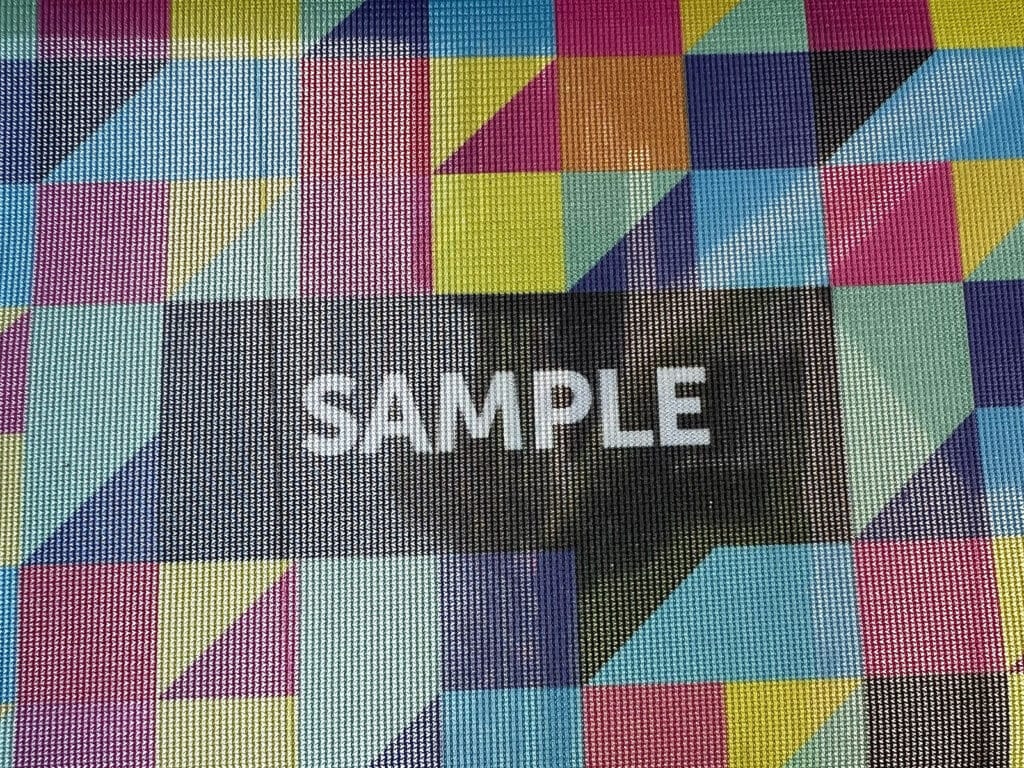

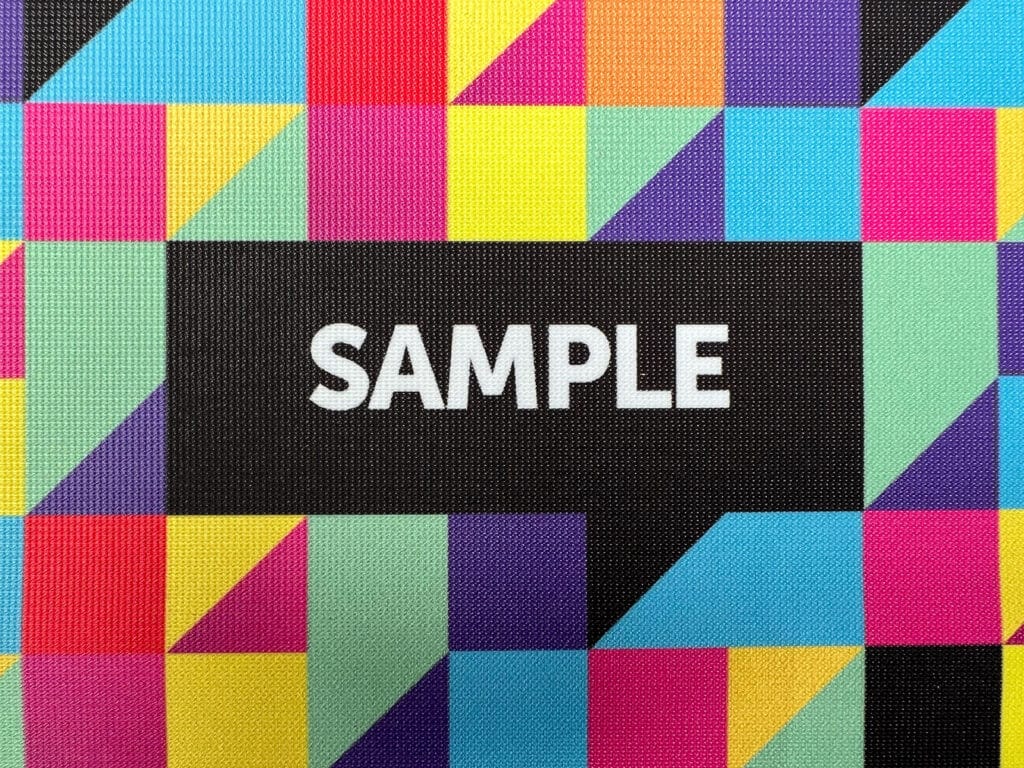

When it comes to printing on fabrics, dye-sublimation is a popular choice for many businesses. However, one thing that often surprises people is the fact that the colours produced by this process can appear paler than expected. This is due to the nature of the fabric itself – unlike solid substrates, fabrics are made from a weave that is less dense and allows light to pass through the surface. This means that when a piece of printed fabric is placed on a coloured background, it can look significantly different than when placed on a white or black background.

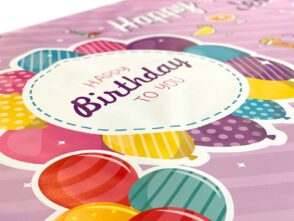

This effect is particularly noticeable with lighter gsm fabrics like 115gsm polyester, which is commonly used to manufacture feather flags. When placed on a white background, a sample of dye-sublimation fabric may appear much paler than expected, with colours like black appearing less dense and vibrant than other print methods. Heavier fabrics like 200gsm display polyester are less affected by this issue, but it’s still important to be aware of the potential for colours to appear paler than expected. Black-back polyester, or black-backed polyester as it’s also referred to, is a full light-stop material. Black-back fabric doesn’t let light travel through the surface, as the reverse of the fabric has a black resin backing. Black back polyester is the ideal material when stopping light travelling through the fabric is a priority.

Why Dye-Sublimation Produces Paler Colors

Dye-sublimation printing is a popular printing method for producing high-quality images on fabrics. However, one common issue with this printing method is that it produces paler colours compared to other printing methods like solvent, latex, and UV printing. In this section, we will explore the reasons behind this issue and how it affects the final output of dye-sublimation printing.

Polyester 115gsm (Feather Flag) Fabric Print against a white background

Polyester 115gsm (Feather Flag) Fabric Print against a black background

Polyester 115gsm (Feather Flag) Fabric Print against a window

Print Sample onto Polyester Black Back Fabric

The Science Behind Dye-Sublimation Printing

Dye-sublimation printing is a chemical process where the ink is first printed onto a transfer paper and then transferred onto the fabric using heat and pressure. During this process, the ink turns into a gas and penetrates the surface of the fabric, resulting in a permanent image. The ink used in dye-sublimation printing is transparent, which means that the colour of the fabric will partially show through, resulting in paler colours.

Effects of Light on Dye-Sublimation Fabrics

The density of the fabric plays a significant role in the final output of dye-sublimation printing. Fabrics with a looser weave or lighter weight, like 110gsm polyester used for feather flags, will appear much paler when placed on coloured backgrounds. This is because the fabric’s surface lets light pass through, making it less dense than other printing methods that print onto solid substrates. Additionally, fabrics placed against a window or an overhead light will appear even paler as the light shines through the surface.

Impact of Fabric Weight on Dye-Sublimation Colors

The weight of the fabric also affects the final output of dye-sublimation printing. Heavier fabrics like 200gsm display polyester have a much tighter weave, resulting in less light passing through the surface. The effects of the material becoming paler in colour are less noticeable, but they still affect the material.

Colour Saturation in Dye-Sublimation Printing

One important factor to consider when printing with dye-sublimation is colour saturation. It is possible to oversaturate colours on printed dye-sublimation, and the combined value of 300% of all ink is the maximum that can be printed onto the fabric. This means that a CMYK mix should not have a combined value of more than 300%. For example, a mix of Cyan 70%, Magenta 70%, Yellow 70%, and Black 100% is too high as the total percentage of ink to the substrate is over 300%. This means that any colours on your screen that have more ink and appear darker on your screen will not print any darker as the maximum saturation has already been achieved.

In conclusion, dye-sublimation printing produces paler colours because of the transparency of the ink, the density of the fabric, and the impact of light on the fabric. It is important to consider these factors when printing with dye-sublimation to achieve the desired color output.

Advantages and Disadvantages of Dye-Sublimation Printing

Dye-sublimation printing is a popular printing method used for producing high-quality, long-lasting prints on a variety of substrates, including polyester fabrics, hard goods, and home décor. The process involves transferring dye from transfer paper to a substrate using heat and pressure. While dye-sublimation printing has many benefits, there are also some limitations to consider.

Benefits of Dye-Sublimation Printing

- High-Quality Prints: Dye-sublimation printers produce prints with high resolution and a wide colour gamut, resulting in vibrant and accurate colours. The prints have a continuous tone, which means that each and every dot of ink can be a different colour, resulting in amazing colour fidelity.

- Long-Lasting: Dye-sublimation prints are resistant to fading, smudging, and water damage, making them a good choice for long-lasting prints. The dye is infused into the substrate, resulting in prints that are embedded in the fabric or substrate itself, not just on the surface.

- Versatile: Dye-sublimation printing can be used on a variety of substrates, including polyester fabrics, hard goods, and home décor. The process is also compatible with a range of equipment, including printers, heat presses, and transfer paper.

- Washable: Dye-sublimation prints are washable, making them ideal for printing on apparel and other textiles that require frequent washing.

- Affordable: Dye-sublimation printing is an affordable printing method, making it accessible to a wide range of businesses and individuals.

Limitations of Dye-Sublimation Printing

- Limited Substrates: Dye-sublimation printing is limited to substrates that can withstand high temperatures and pressure. This means that it is not suitable for printing on substrates such as cotton or other natural fibres.

- Limited Ink Options: Dye-sublimation ink is typically limited to disperse dyes, which are designed to work with polyester and other synthetic fibers. This means that it may not be possible to achieve certain colours or colour combinations.

- Limited Color Depth: Dye-sublimation printing can produce vibrant and accurate colours, but it may not be able to achieve the same depth of colour as other printing methods, such as pigment-based inkjet printing.

- Equipment Requirements: Dye-sublimation printing requires specialised equipment, including a dye-sublimation printer, heat press, and transfer paper. This can make it more difficult and expensive to get started with this printing method.

In conclusion, dye-sublimation printing is a versatile and affordable printing method that produces high-quality, long-lasting prints on a variety of substrates. While there are some limitations to consider, the benefits of dye-sublimation printing make it a popular choice for businesses and individuals looking to create high-quality, long-lasting prints.

Leave a Reply

You must be logged in to post a comment.